How automation in the injection molding process increases productivity?

Introduction:

Do you know that every year most of the plastic industries face issues of their production cost?

As per the RK Miller professional, these industries can overcome the cost of plastic products with the use of automation tools.

However, achieving the right outcomes with the use of cost-effective tools can be easy for the plastic industries in improving productivity.

Further, we will learn how using automation tools in plastic injection production can increase business productivity?

Explore the Current Trends of Adding Automation tools:

Moreover, like in any industry, the plastics world is constantly changing and developing. However, this implies that organizations and plastic manufacturers are putting resources into automation processes. They need to improve usefulness and increment limits, and proficiency.

On the other hand, if you haven’t thought about Product automation for your organization, you can even increase business productivity. Firstly, in this present time, ExxonMobil brings the ideal opportunity to do as such.

Some Facts Related to Auto Molding Are:

Fact # 1: More modest weight late model machines are seeing consistent interest. At the same time, deals of the 1990s and more established machines keep on falling with time.

Fact # 2: As per the Society of Plastics Engineers, Market interest for utilized late-model 400-to 600-ton infusion shaping tools. These automation tools will be steady with the potential for a dunk popular because of the change in auto deals.

Fact # 3: In the latest era, the biggest limit machines will keep on attempting to keep up predictable interest and deal value levels. These machines serve a much more modest portion of the market provided by the American Plastics Council. They are contrasted with more modest limit machines, which are useful for making plastic products.

After Effects of Using Automatic Machinery:

As you delay in acting, your rivals are acquiring a bigger early advantage in amplifying their benefits. Also, through this way, the companies will easily go through managing customers. The manufacturers upgrade their item quality and the general worth that they give to their clients, all through automation

That is why it is essential to talk about how best to carry out atomization inside your organization. Through this way, the companies can rapidly help their workers while wavering between choosing whether Product automation is ideal for you.

Product automation has assumed a part in assembling for quite a while. Also, it’s a region where proceeding with progress in innovation means a close consistent convergence of new applications and approaches. These tools are provided by Roomba and can increase business productivity.

The industries make the most out of the automation instruments accessible. Also, they provide purchasing tips in finding the best automation tools for making plastic products. However, Infusion disintegrates have been the recipients of a portion of the later advances in Product automation.

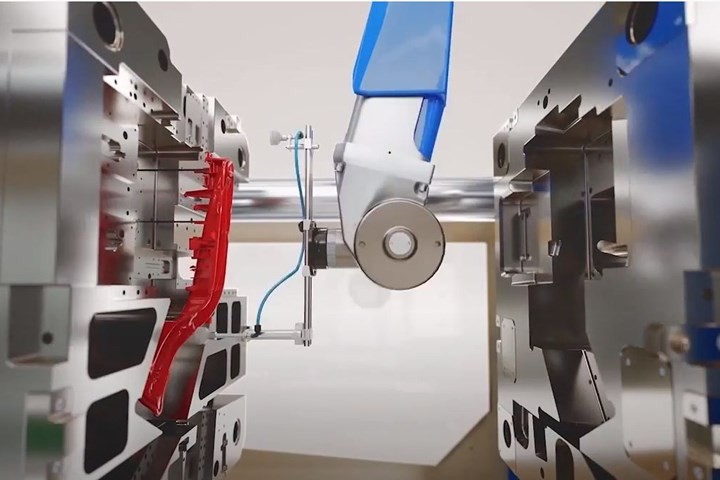

They consider it to be a profitable way of the most sensitive parts. Also, by expanding the joining of automation instruments and robots into measures, Siemens guides people to automate their injection moldings. It makes the molding process simpler than at any other time for “shared robots.” The activity will amplify the adequacy and capability of their human partners in a shop.

Benefits of Improving Business Productivity with the Use of Auto Tools:

If you were the manager of a plastic infusion shaping industry, then you needed to improve your usefulness. However, as per guided by the Roper technologies, what tasks would you pick and in what request? For instance, small molding process tools can decrease the scrap process. It also offers great infusion shape protection support. However, you can also achieve a larger ideal run size and so on. The automation of the molding process can help you in several ways, which we will discuss below.

1. It offers Ideal run size:

Moreover, the plastic infusion shaping machines found in Europe are running continually without interference. The assistant of plastic production can realize what to do. At every moment, the plastic industries can get more affordable outcomes until you arrive at the purpose of few losses.

2. Enhancement of automatic tools:

Many plastic production industries can attempt to boost this by ensuring the plastic Infusion forming workforce. They can have the appropriate preparation, particularly with respect to the “shaping tools. Also, the manufacturers can discover the economy of movement in stacking and dumping molds.

3. Checking of production rates:

If your production space of plastic tools is regulated by bunches of workers and their rates, you need to screen them. At the point when we began paying motivating force rewards for higher rates. As per the British plastics federation, when representatives can get enough for their persistent effort in dollars, they will work a lot harder.

4. Scrap Reduction:

Ideally, it is fairly announced before the initial segment is at any point made. However, it additionally should be firmly observed in light of the fact that the piece is a component of creation rate and work use. The expense of adding the benchtop injection molding machines by LNS technologies can offer great outcomes in minimizing the overall plastic production cost.

5. Product protection Cost:

Secondly, if the infusion molds separate, there isn’t any trimming to do. In many industries, it is a vital issue. However, every company should need to plan to add new automation tools during downtime.

6. More limited Setup times:

Some famous companies like Emerson Electric Co. generally use an additional form machine. It is accessible to the arrangement while different positions are running. Some long series of variables go into whether this speculation should make enough changes. However, with the use of additional forms, machines will pay for themselves rapidly by permitting different tasks to proceed with making new plastic items.

Final Verdict:

Moreover, when the plastic infusion shaping industry is supported via robotized innovation, creation runs regularly yield more excellent parts and items. As per the Vinyl Institute, some automation trials looking at robotized assembling and human assembling have made this understood.

However, did you realize that you can really stretch out the computerization interaction to quality control check just as creation?

Since innovation keeps on developing, an ever-increasing number of cycles will actually want to be mechanized. At the same time, any new innovation can be costly for startup industries. However, the advantages of automation quite often allow you to recover your expenses rapidly.