Introduction

As you know, there are a variety of toxic and unsightly fume extraction system produced within today’s manufacturing plants. You certainly don’t need injured employees or the other “action” to delay your production. The answer to this severe and dangerous dilemma is quite simple, an air purification system.

There is a spread of such products available. They vary from free-hanging fans and filter packages to full exhaust systems, downdraft tables, blowers, modular ventilation systems as well as portable units.

Things You Need Before Test your Fume Extraction System

If your air cleaning goes to require a spread of filtration media to handle varying economic conditions, a “free-hanging” or “packaged” air filter could instead be your best route to success. Large washable filtration systems strain then re-circulate the air via a race track, or the more standard cross dilution, mounting configuration. As an additional benefit, such systems can handle any of your chemical absorption needs also.

When the air is contaminated with particulate, dust and fume collectors are economical methods to make sure a clean atmosphere. On-line cleaning without significant loading allows for constant internal static pressure to be maintained. Therefore, the resulting particle is recovered from the rock bottom of the group.

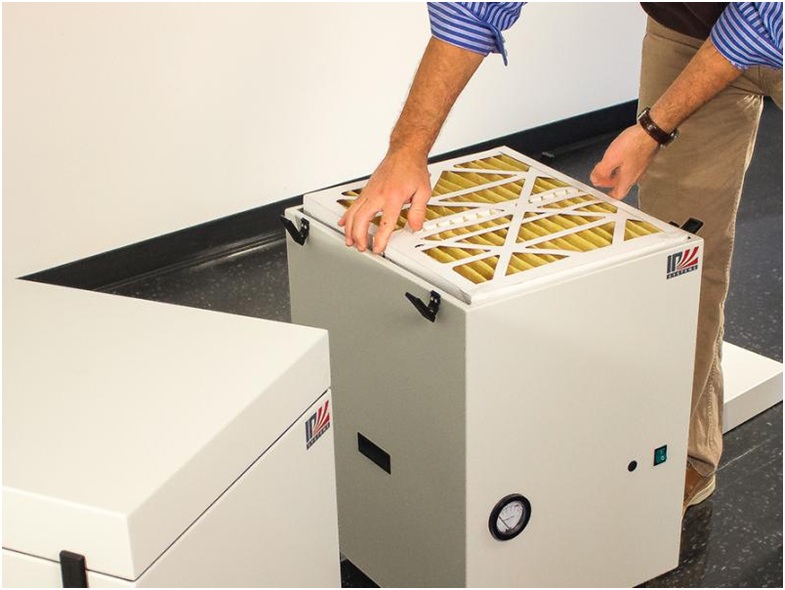

Here’s one to observe out for aluminum dust within the air. These tables are available in a sort of sizes, depending upon your use requirements. Many fume extraction system are portable and offer easily detachable panels and doors for maintenance and filter removal.

With a garage operation, you are required to ensure vehicle exhaust exits the work area. There are low-cost, pure hose drops for handling fumes, smoke and even light dust from the air. Using fans, they’re usually mounted on to a bracket, an extraction arm, filter units and hose reels. These fans can also be portable to be used in various work areas when needed. These direct mount fans also are available in low and heat models. They may also be equipped with rope, pulley kit and saddle, a balancer, with an extension boom or maybe an articulating crane for fan positioning on any side of a vehicle.

Blowers and exhaust fans are standard components incorporated into many fume extraction system. There are direct-drive fans, belt-driven fans, and native exhaust fans. Plus, the right fan also can make sure the proper flow and static pressure for your specific application.

Fume Extraction Survey

The first thing to consider is that you need a fume extraction system for, for instance:

- welding

- plating tanks

- glueing

- paint spraying

- fiberglass laying out

- screen printing

Conclusion

Once this is often established, and therefore the sort of fumes that are to be removed, thoughts are often directed into what method of capture will be used, the ducting route needed, and a selected method of fume removal from the air before discharge into the atmosphere. With thousands of industrial fume extractors installed, ipsystemsusa.com have the expertise and experience to ensure customer satisfaction.