Isn’t it fascinating that a common robotic vehicle is used in a military operation for bomb detection? The one that makes a common robotic vehicle a bomb detection device is a servo motor. To know more about the motor, keep reading.

What is a servo motor?

A servo motor belongs to a closed-loop system or path. These paths included several parts like a control circuit also called servo circuit (วงจร เซอร์ โว, which is the term in Thai), servo motor, shaft, amplifier, and an encoder or resolver. A servo motor is basically an electrically self-contained device that helps a machine to work with high efficiency by rotating the parts of the machines. Servo motors ensure the machine works with great precision. The Servo motor has an output shaft that can be moved at any particular angle, position, and velocity. When compared, regular motors lack these output shafts that move according to the required angle and velocity.

Construction And Working

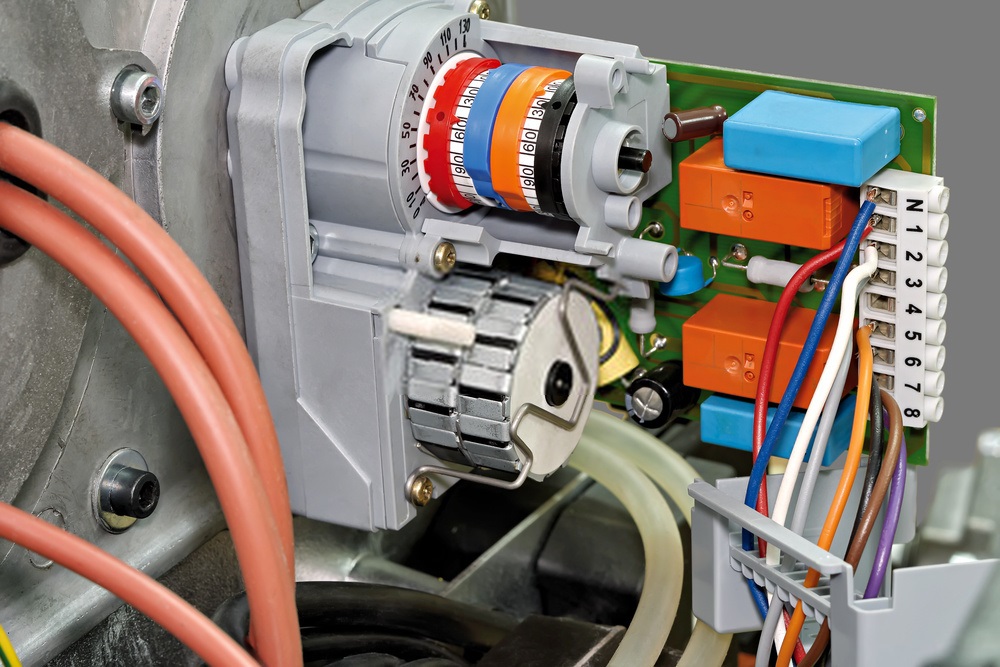

- A servo motor uses a servo circuit, a regular motor that is attached to a sensor with an intention of receiving positional feedback.

- Being a closed-loop mechanism, the servo motor integrates positional feedback. It helps by controlling the rotational or linear speed. Managing the speed is also an application of servo motors. Analog or digital electric signals are used to control the motor. These electric signals play a vital role in deciding the final command position of the shaft.

- To receive position feedback and to know the speed provided, an encoder is used. This encoder is used as a sensor.

- This servo circuit is constructed inside the housing of a motor. The inner part of the motor is usually suited with a gear system.

There are different servo motors classified according to their applications.

Types Of Servo Motors Based On The Current Type

- AC Servo Motor

- DC Servo Motor

The main difference between these two motors is their ability to take over the speed. In a DC servo motor, speed is directly proportional to supply voltage. In an AC servo motor speed is calculated by the frequency of the applied voltage.

Types Of Servo Motors Based On The Commutation Used

- Brushed Servo Motor

- Brushless Servo Motor

Brushed motors are cost-effective and are easy to operate while brushless motors are reliable and create less noise.

Types Of Servo Motors Based On The Motor’s Rotating Field

- Synchronous Servo Motor

- Asynchronous Motor

In a synchronous motor, both the stator’s rotating speed and rotator speed are equal. In an asynchronous motor, the rotator has less speed.