Are you in the market for a reliable machining partner that can help take your metalworking projects to the next level? Sheet metal machining is one of the most cost-effective and efficient ways to create solid, precisely formed parts for many uses. In this blog post, we will explore some of the key benefits of sheet metal machining and how it could revolutionize your production process.

From superior accuracy to personal customization options, a reliable manufacturer capable of providing quality sheet metal fabrication services can deliver incredible value to any product or system.

Whether you’re looking for components with tight tolerances, intricate shapes that would be difficult via other methods, or more flexibility when incorporating various materials into your designs, machining could be the perfect choice! Read on to learn why our company stands out as a leader in precision machinery manufacturing and what sets us apart from our competitors.

What is Sheet Metal Machining, and How Does It Work?

Sheet metal machining is the process of shaping and cutting metal sheets into different shapes and sizes. It involves the use of specialized tools, machines, and techniques to transform raw metal materials into finished products that are ready to be used in various applications.

This process includes a variety of techniques, such as bending, punching, drilling, and cutting, that require skilled professionals who are trained to work with different types of sheet metal materials. Sheet metal machining has revolutionized the metalworking industry by enabling the creation of complex, high-quality products with precision and accuracy. From the aerospace to automotive industries, sheet metal machining has played an invaluable role in shaping modern-day products that consumers use daily.

The Advantages of Working with a Professional Machining Manufacturer

When it comes to machining parts and components, working with a professional manufacturer can bring countless advantages to the table. First and foremost, you gain access to the latest technology and equipment, which can result in a higher-quality finished product. Additionally, professional manufacturers have a team of experienced engineers and technicians who can troubleshoot issues and provide tailored solutions to meet your specific needs.

This eliminates the need for costly trial and error that can come with working with less experienced machining suppliers. Finally, professional manufacturers often offer a wider range of services, from design and prototyping to finishing and assembly, that can streamline your entire production process. By partnering with a reputable machining manufacturer, you can rest assured that your project is in capable hands.

How to Select the Right Metal for Your Project

Choosing the right metal for your project can be a daunting task. With so many options, from aluminum to zinc, it’s essential to factor in key specifications such as strength, durability, and weight. One of the most critical considerations is the environment in which the metal will be used. For example, if your project will be in a marine environment, it’s best to select a metal such as titanium or stainless steel that has excellent resistance to corrosion.

Additionally, think about the aesthetic appeal you’re trying to achieve. Some metals may shine brighter, be more malleable, or have a unique color. Taking the time to research and understand the characteristics of each metal will ensure you choose the best one for your project, and the result will be a product that will last for years.

Design Considerations When Working with Sheet Metal

Designing with sheet metal requires careful consideration of various factors in order to achieve the desired outcome. Material thickness, bend radius, and hole size are just a few of the aspects that must be taken into account. It is important to have a thorough understanding of the properties of the metal being used and to choose the appropriate processing techniques to ensure the final product meets all necessary requirements.

Design for machine manufacturability is also crucial, as small design changes can have a significant impact on production efficiency and costs. By working with an experienced sheet metal fabrication team, designers can ensure that all design considerations are taken into account and their vision is brought to life efficiently and effectively.

Understanding the Different Types of Sheet Metal Machining Processes

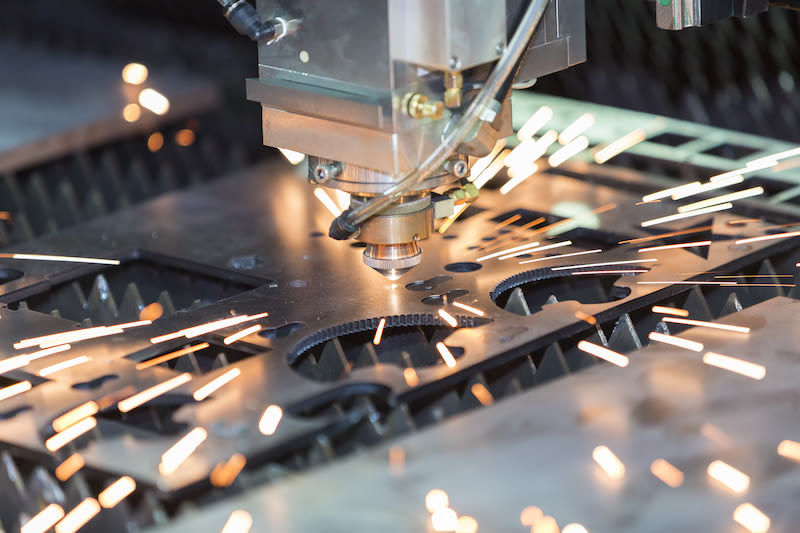

Sheet metal is a vital component in the manufacturing of various products. Understanding the different types of sheet metal machining processes is crucial to producing high-quality sheet metal parts. There are several methods for sheet metal machining, including laser cutting, water jet cutting, and punching, among others. Each method has its advantages and disadvantages, and selecting the right method depends on various factors such as the material type, thickness, and desired finish.

Laser cutting, for example, is ideal for thin sheet metal, while water jet cutting is better suited for thicker materials. Whether you’re in the automotive, aerospace, or construction industries, having a basic understanding of sheet metal machining processes can go a long way in ensuring your products’ precision and accuracy.

Tips for Successful Sheet Metal Machining Projects

When it comes to sheet metal machining projects, there are a few tips that can help ensure success from start to finish. First and foremost, it’s important to have a clear plan in place before diving into the project. This includes detailed designs, accurate measurements, and a thorough understanding of the materials and tools needed. Additionally, maintaining a clean and organized workspace can help prevent mistakes and make the machining process go smoother.

It’s also important to stay patient and take your time, as rushing through the project can lead to errors that may cost time and money down the line. Finally, seeking the guidance and expertise of experienced sheet metal machinists can provide valuable insights and ensure that your project is completed to the highest standards. With these tips in mind, your sheet metal machining project is sure to be a success.

Sheet metal machining is an essential part of the manufacturing process for many industries, from consumer electronics to biomedical devices. It requires precise materials, processes, and expertise to achieve optimal results. Working with a reliable machining manufacturer is the best way to ensure that your project is successful.

A good machining manufacturer will review your design specifications and guide you through the process from start to finish, helping you find the right type of metal for your project, create a detailed plan for its production, and consider any design elements necessary for a successful machining process.

With the right team on your side, you can be sure that your sheet metal machining project will be completed on-time and on budget, offering you great-quality components that meet all of your specifications.