A thread gauge, also known as a screw gauge or pitch gauge, is used to measure the pitch or lead of a screw thread.

Thread pitch gauges are used as a reference tool in determining the pitch of a thread that is on a screw or in a tapped hole. This tool is not used as a precision measuring instrument, rather it allows the user to determine the profile of the given thread and quickly categorize the thread by shape and pitch. This device also saves time, in that it removes the need for the user to measure and calculate the thread pitch of the threaded item.

To use a thread gauge, the user must first match the type of thread to the gauge. For example, attempting to measure metric threads with an imperial gauge will not return accurate results. To determine the correct gauge, a process of trial and error may be needed if the screw is of unknown origin. Therefore, numerous types of thread gauges are available and one of the most important types is trapezoidal thread gauge.

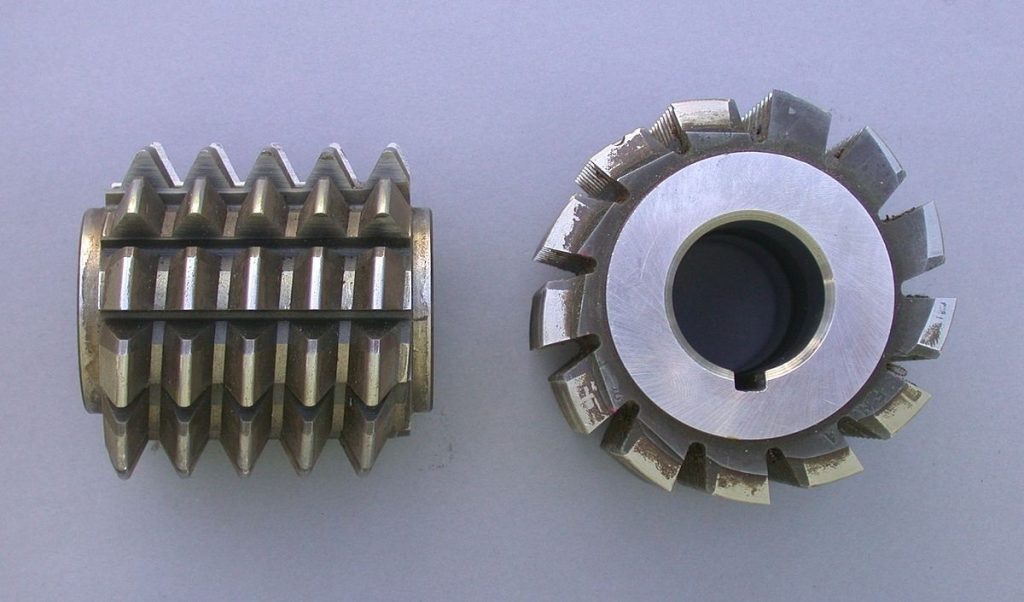

Trapezoidal thread gauges

Trapezoidal thread forms are screw thread profiles with trapezoidal outlines. They are the most common forms used for leadscrews (power screws). They offer high strength and ease of manufacture. They are typically found where large loads are required, as in a vise or the leadscrew of a lathe.

The trapezoidal metric thread gauge is similar to the Acme thread gauge, except the thread angle is 30°. While metric thread gauges is more prevalent worldwide than imperial threads for triangular thread forms, the imperially sized Acme threads predominate in the trapezoidal thread form.

The uses for these thread forms are essentially the same. In fact, taking manufacturing tolerances allowed into consideration, they may be interchangeable when TPI (threads-per-inch) is the same. Both thread forms serve the purpose of producing linear motion when rotated, usually under heavy load. Some common uses include; lead screws for linear actuation on CNC machinery, table lifts, clamps and vises, valve stems, medical diagnostic device drives, trailer jacks, and jack-stands.

The demands placed on the tools that produce these threads are higher due to the amount of material being removed, per tooth, in the process. Controlling “chip-load” is critical. In order to design tap for these threads, North American Tool requires specific detail on the application. Information on the material being tapped, tapping depth, condition of the hole (through or blind), and Class of Fit is essential to engineer the proper tap. General purpose taps are availabl but are definitely not suitable for every application.

These are basically dimensional instruments and are needed to verify the size, pitch and other parameters of the thread. If your business includes measuring the threaded parts, you will understand the importance of having quality based thread gauges. It is important to have thread gauges in today’s industrial world as accuracy is a thing which matters the most and without this gauge family, it cannot be achieved.